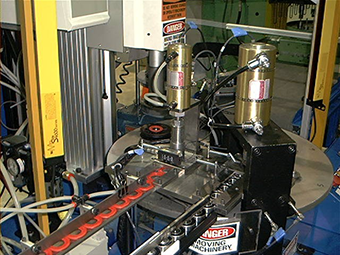

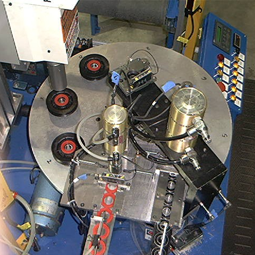

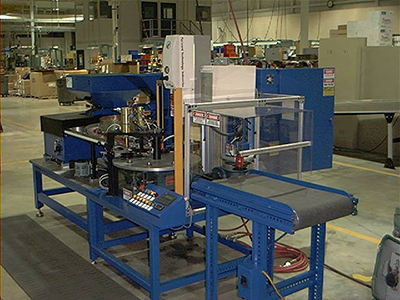

Semi-automatic dial index machine for the presswork assembly of radial ball bearings and dust seals into belt pulleys of varying diameter

The machine inserts radial ball bearings and dust seals into vee-belt pulleys. With each cycle, an operator manually loads a molded plastic pulley to the indexing dial-plate, and the pulley runs through three presses (two pneumatic and one ultrasonic) to complete the assembly. The bearings and seals are bulk-fed through vibratory bowls and inline tracks, and the finished pulleys are transferred from the index dial to an exit conveyor by a cam-driven electromagnetic pick-and-place. Descher engineers worked with the customer’s staff to coordinate on-and-offsite build schedules to upgrade all control hardware and replace existing tooling with modular nest fixturing. The result was a machine with increased manufacturing flexibility through minimal impact to production requirements.