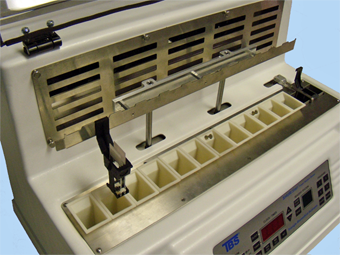

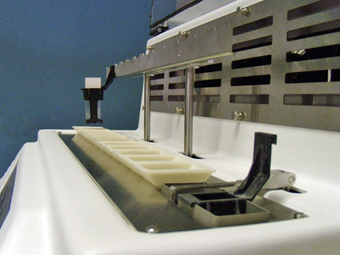

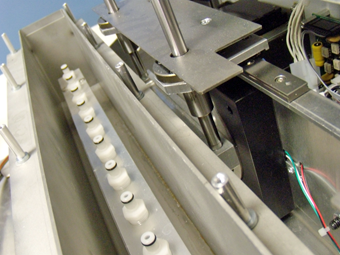

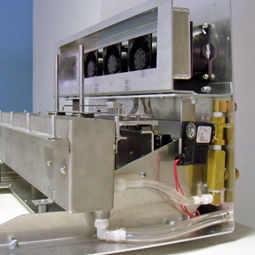

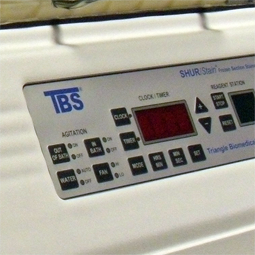

Ground-up design and prototyping of an economical (yet feature-rich) semi-automatic frozen section stainer for use in histological laboratories

Descher worked with the customer to indentify existing products in the marketplace and develop a feature-focused competitor matrix. From there, Descher worked with the customer's engineering staff to champion the FSS' mechanical design and collaborate on its controls development, from board-level electronics to the custom user interface. After the project design, Descher launched the FSS prototyping phase, augmenting in-house capabilities with laser-cutting, rapid prototyping, and thermoforming shops to build out a five-unit pilot program.